SINTROL Dust Monitoring and Dust Detection

Sintrol offers high-quality, process-oriented solutions for the detection and monitoring of particles after bag filters and dedusting installations.

The measuring principle is based on a unique inductive electrification technique. As particles pass or hit the sensor, a signal is generated which is amplified and analyzed by a series of Sintrol’s advanced algorithms to filter out noise to determine an accurate level of dust.

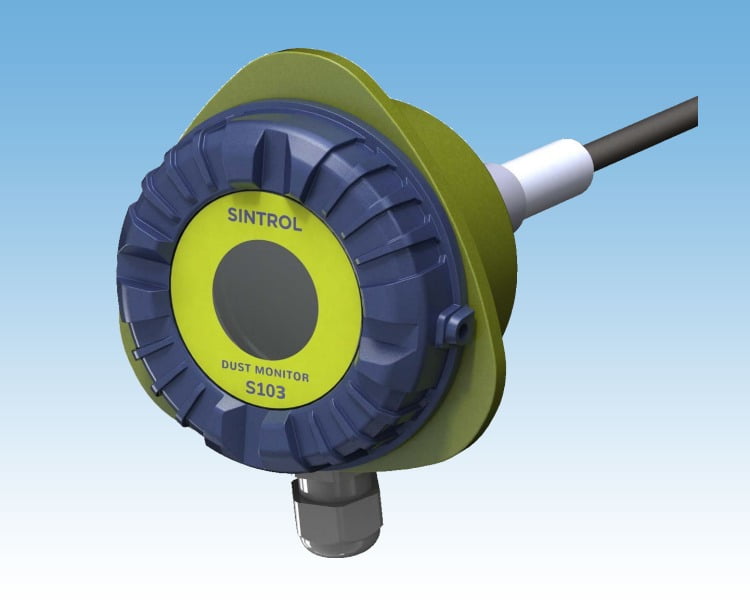

FILTER LEAK DETECTION

Wherever single or multi-compartment bag filters are used in the process, Sintrol S100 series dust detectors are the perfect solution for detecting filter quality degradation or filter breakthrough. Timely detection can prevent an excessive amount of dust from ending up in the environment. The Sintrol S100 series are low maintenance and can detect dust levels from 0.01 mg/m³.

Also available in ATEX models.

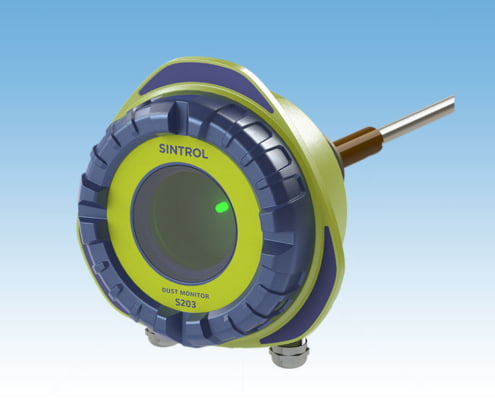

DUST MONITORING

The Sintrol S200 series consists of the S201 Dust Guard with 2 alarm outputs, and the S203 Trend Monitor with additional 4-20 mA output. Both are suitable for a supply voltage of both 24 VDC and 100-240 VAC. They have a Quick Clamp process connection as standard and are suitable for temperatures up to 300 °C and 600 kPa pressure.

Also available in ATEX models.

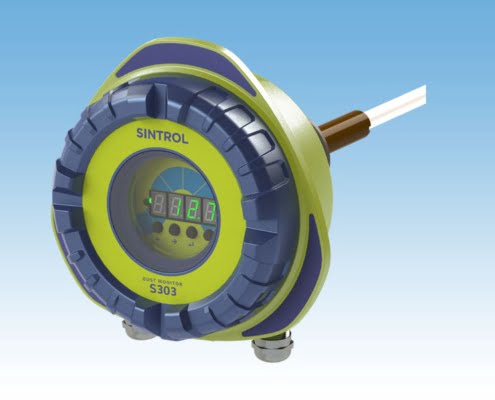

PROCESS MONITORING

In many large or combined output channels, a continuous trend measurement is used to gain insight into the dust level in the process. The Sintrol S303 is, in addition to 2 alarm outputs, equipped with a 4-20 mA output. High temperature versions (up to 700 °C) are available, providing a solution for almost all applications.

For companies that use Electrostatic Precipitators (ESP), the Sintrol E-SPY is the only sensor-based monitor with a 4-20 mA output for continuous trend measurement after an ESP. This gives the user insight into the efficiency of the ESP and the possibility to optimize the process.

Also available in ATEX models.

EMISSIONS MONITORING

Sintrol’s unique Inductive Electrification measurement method has made it possible to develop monitors to provide accurate measurement data of dust emissions in mg/m³.

For each stack in the plant, Sintrol’s S304 and S305QAL monitors can be calibrated to provide readings in mg/m³ for actual emissions amounts. Sintrol’s S305QAL monitor is a TÜV certified instrument, meeting the QAL1 standards, for official emissions measurements in the European Union.

These virtually maintenance free monitors are a less expensive and more reliable alternative to the traditional opacity monitors that have been used historically.

Also available in ATEX models.

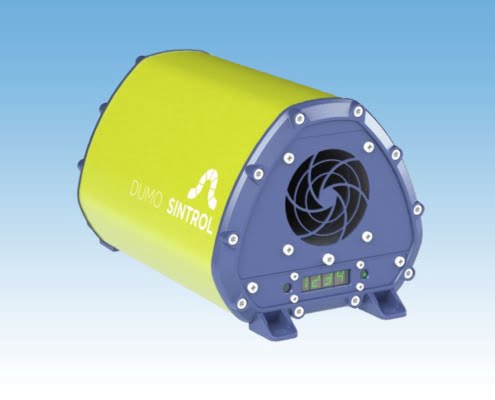

AMBIENT MONITORING

Sintrol’s Dumo family expands our technology to measure dust in ambient air conditions. In welding areas, warehouses, or other environments with high ambient dust concentrations, we can measure relative levels of harmful dust in the work environment. With a continuous 4 – 20mA signal output as well as “Alert” and “Alarm” functions, plant operators can measure the dust concentration levels in the workplace. The same solution has also been used in coal storage yards and for urban dust measurement.

Like the process and emission monitors, the DUMOPRO is equipped with the Inductive Electrification measuring principle.