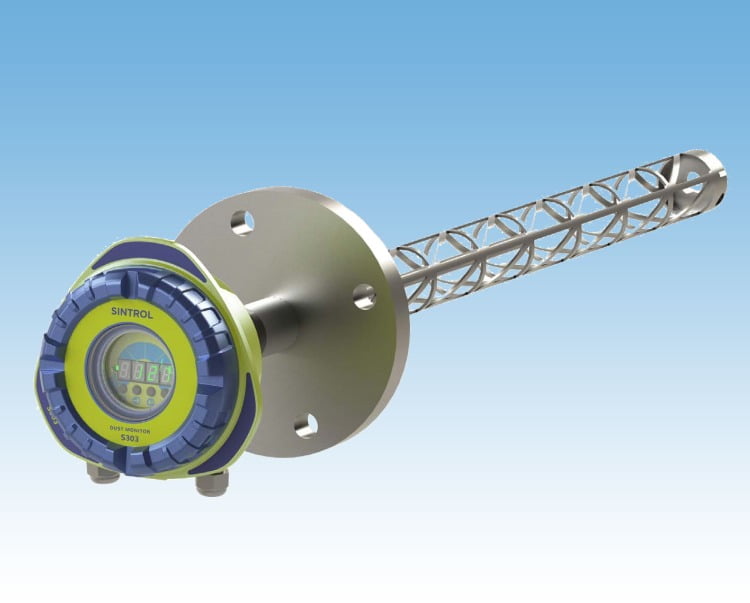

Continous dust monitor for post-ESP applications

As the only probe based dust monitor proven to be a reliable trend monitor after electrostatic precipitators (ESP), the Sintrol ESPY is one of its kind. With the ability to neutralize the electrostatic field in the outlet duct of an ESP, the ESPY is able to give a trend of relative dust concentrations to help plant operators optimize the use of the ESPs.

Industrial Applications:

- Power/electricity generation

- Cement industry

- Chemicals industry

- Metals industry

- Paper industry