DustLog 8 is the premier central management solution for dust measurement equipment.

It gives plant operators full control over the network of dust monitors with efficient parameterizing, reporting and networking functions on an easy to use interface. By unifying all of Sintrol’s latest technology into one management tool, DustLog 8 brings not only greater convenience and usability, but also improves plant efficiency, network management and worker safety for the end user.

The DustLog 8 PC software can be connected via a network router to the dust monitors. RS485, Modbus and RF are supported.

Sintrol’s monitors that are equipped with RS485 and USB networking capabilities will automatically network themselves in the most optimal manner without any manual parameterization. When the system needs to be extended with additional monitors, the software will locate and identify the new devices automatically. Regardless of the number of units spread around the plant or factory, you can communicate to all of the devices from one computer. Additionally, the easy user interface gives the plant full control of the device’s parameters so they can be read, sent or configured directly from the control room.

Not only is it more efficient to be able to manage multiple devices from one location, it also improves worker safety by keeping people away from dangerous installation locations in the plant.

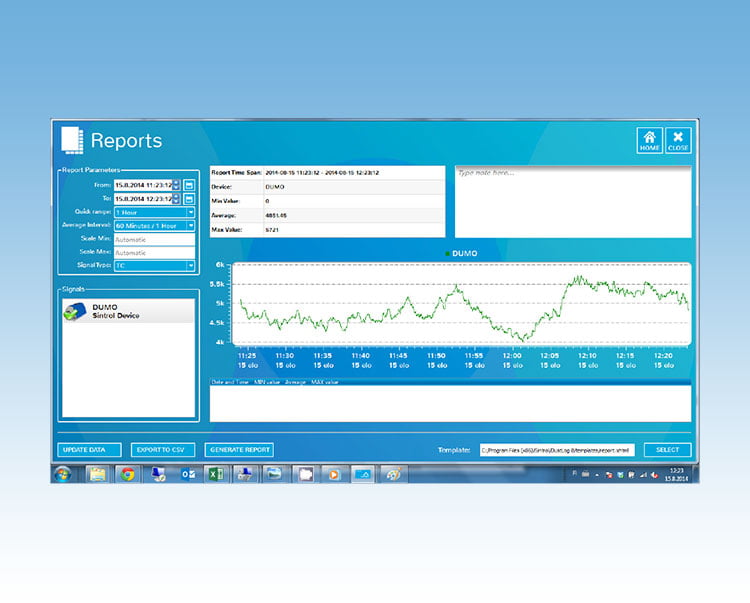

Whether for internal usage or government authorities, a wide range of reports can be generated to see historical trends in the measurement with monthly, daily or hourly self-explaining graphs.

For official emissions reporting, the measurement history can be logged and analyzed over a period of time to give regulators the information they need. For trend monitoring and broken bag detection, plant operators can quickly see historical trends of the filter systems to optimize the filtration systems.

Amongst its many features are:

- Data acquisition and processing

- Comprehensive data storage

- Remote parameterization (averaging time, alarm limits, alarm delay times, etc.)

- Remote calibration of the mA and mg/m3 outputs

- Remote auto setup function and history based calibration

- Export data to third party softwares (e.g. MS Excel)

- Measurement history and reporting functionality

- Offsite data storage into multiple supported database servers

- Automatic setup and network management with multiple instruments and connections – It can combine different physical connections within the same network.

- Real time monitor views of various measurement points

- Compatible with PostgreSQL, SQLite, SQL Server