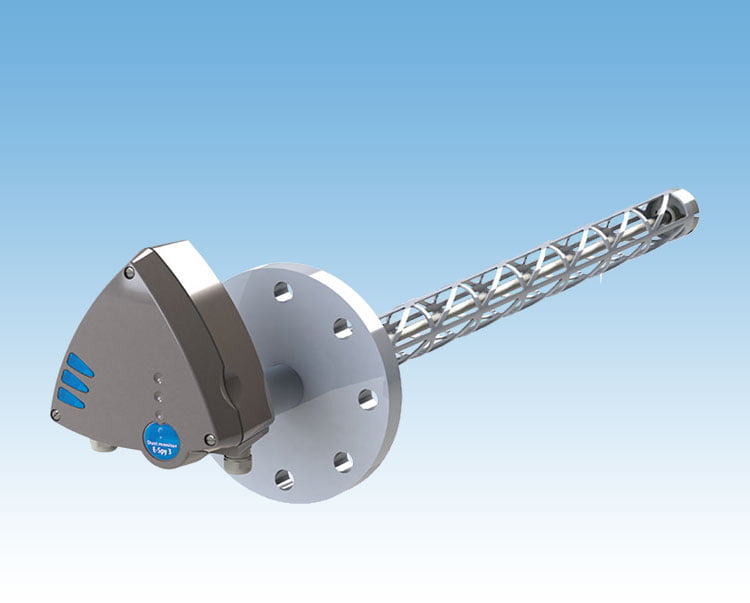

Continous dust monitor for post-ESP applications

As the only probe based dust monitor proven to be a reliable trend monitor after electrostatic precipitators (ESP), the Sintrol ESPY is one of its kind. With the ability to neutralize the electrostatic field in the outlet duct of an ESP, the ESPY is able to give a trend of relative dust concentrations to help plant operators optimize the use of the ESPs.

ATEX Models

- Certified for ATEX Zone 20, 21 or 22

- Approved to Category II 1/2 for Gas and Dust

- IP65 Enclosure, Custom Designed ● Certification Type: II 1/2 GD EEx ia IIC, T6, IP65, 85°C

- Utilizing SINTROL’s Advanced Inductive Electrification Technology

The ATEX directive covers health and safety of workers potentially at risk from exposure to explosive environments. This directive classifies areas into Zone 0, 1, 2 for gas and 20, 21 or 22 for dust and guides plant operators to install the appropriate ATEX certified systems. Products are required to be categorized by the level of protection that they offer against the risk of them becoming a potential source of ignition in an explosive atmosphere. The equipment conformity categories are 1, 2 & 3.

E-Spy

| Measurement Objects | Solid particles in gas flow |

| Particle Size | 0.3 µm or larger |

| Measurement Range | From 0.1 mg/m³ |

| Measurement Principle | Inductive Electrification |

| Protection Category | IP65 |

| Probe Length (total/measuring) | 500mm/440mm, 1000mm/940mm, 1500 mm/1440mm19.7″ / 17.3″, 39.4″ / 37.0″, 59.1″ / 56.7″ |

| Power Supply | 115 VAC, 230 VAC or 24 VDC |

| Power Consumption | DC model Max 3 W, AC model Max 8 W |

| Wiring Connections – Power Supply | DIN PG11 cable gland |

| Wiring Connections – Output Signals | DIN PG11 cable gland |

| Process connection | Flange (DN80), other flange types on request |

| Output Signals | – Isolated 4 – 20 mA – Two SPDT relays: 5 A, 24 V AC/DC |

| Communication Interface | Serial communication RS-485 |

| Range Set Up | – Normal measuring range: automatic, based on average measured dust flow during setup procedure – Extended measuring range: User selectable |

| Relay Alarm Settings | – Automatic, set at factory: Based on average measured dust flow – User selectable ranges |

| Offset Trim | Automatic drift compensation |

| Signal Damping Time (mA) | 0 – 300 s |

Process Conditions

| Temperature | Max 250°C, Max >250°C on request ı Max 482 °F, Max >482 °F on request |

| Pressure | Max 300kPa, Max 600kPa (optional) ı Max 43.5 PSI, Max 87.0 PSI (optional) |

| Gas Velocity | Min 4 m/s ı Min 13.1 ft/s |

| Humidity | Max 95% RH (non-condensing) |

Ambient Conditions

| Temperature | -20 to +45°C and 60°C for 24 VDC ı -4 to +113 °F and 140 °F for 24 VDC |

| Humidity | Max 95% RH (non-condensing) |

| Vibration | Max 5m/s² ı Max 16,4 ft/s2 |

Materials

| Probe (wetted part) | Stainless steel (AISI 316L) |

| Probe Coating (wetted part) | PTFE Teflon (optional) |

| Process Connection (wetted part) | Stainless steel (AISI 316L) |

| Faraday Cage (wetted part) | Stainless steel (AISI 316L) |

| Probe Insulation (wetted part) | PEEK |

| Probe Sealing (wetted part) | FPM Viton |

| Enclosure | Aluminum alloy |

| Weight | 6.8kg ı 15.0 lbs |